PRODUCTS

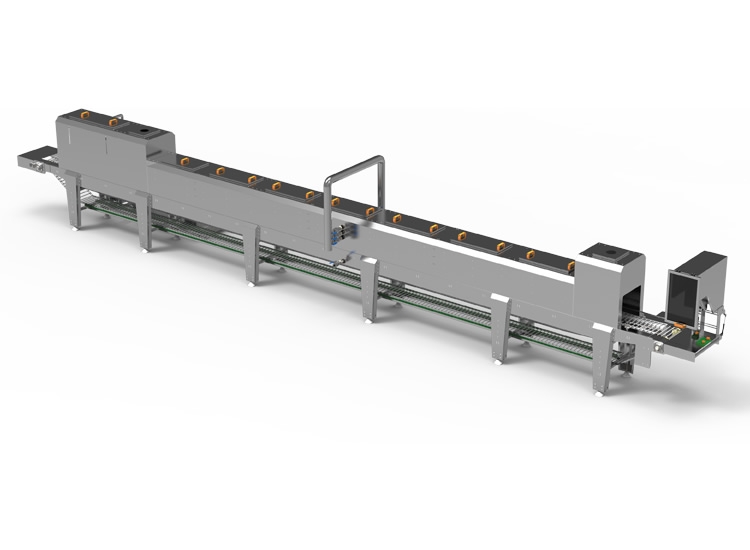

Exhaust Tunnel - 12M

Exhaust tunnel working with the steam boiler, the machine is used in processed and packed olive pasteurization. Olive is pasteurized by brine, filling, pre-heating, baking and cooling processes in the exhaust tunnel. Cooling process is performed by the cooling basin placed at the end of the exhaust tunnel. Conveyor belt speed of the exhaust tunnel can be adjusted by electronic speed control system ungradually. Exhaust tunnel may be manufactured in the desired size and width upon request. The exhaust tunnel is made of stainless steel completely.

- MODEL: CM024

- IP 65 plastic control panel (Hensel)

- 380 V / 50 HZ

- Serial phase protection relay

- Electronic speed control system (Schneider)

- AISI 304L stainless steel body

- Bearings with plastic body and stainless steel housing

- Protection with thermic relay

- Stainless steel braided band

- Heated brine tank

- Brine filling system

- Stainless steel brine pump

- Steam collecting hood fume on the two sides of the tunnel

- Brine heating system with titanium sheet heat exchanger

- AISI 316 stainless steel seamed steam pipes

- AISI 316 steam valves

- Temperature indicator on body and brine tank

- Pneumatic cover closing system at the end of the tunnel

- Worm gear reducer

- Length 13023mm

- Height 1800mm

- Water Consumption Depends on the product

- Capacity (Min./Max.) Depends on the product

- Width / Band Width 860 mm / 337 mm

- Engine Power (Band + Water Pump) 0,37 kw + 0,75 kw

Share This Page :